by

KL Krishna

Bishwanath Goldar

Deb Kusum Das

Suresh Chand Aggarwal

Abdul Azeez Erumban

Pilu Chandra Das The views expressed in this Report are those of the authors and should not be attributed to the Centre for Development Economics as an Institution. © 2022 jointly held by K.L. Krishna, Bishwanath Goldar, Deb Kusum Das, Suresh Chand Aggarwal, Abdul Azeez Erumban and Pilu Chandra Das, the authors of the Report Centre for Development Economics

Delhi School of Economics

University of Delhi

Delhi 110007, India

www.econdse.org |

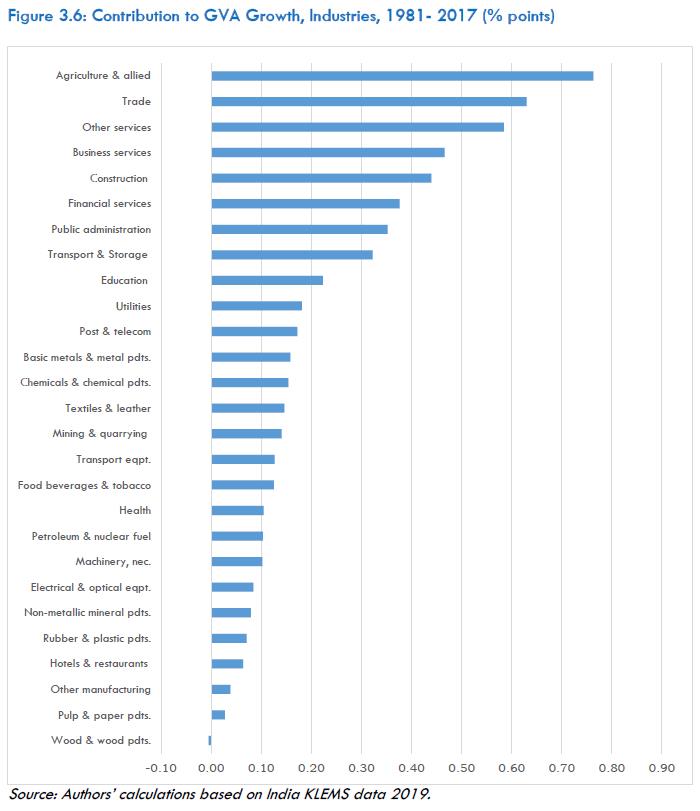

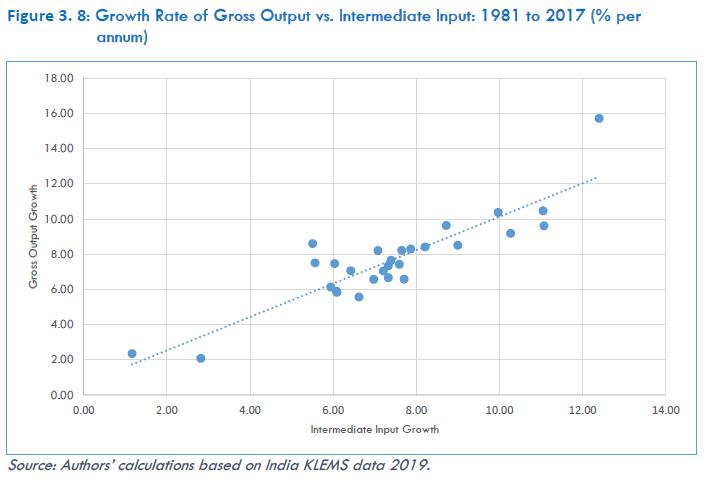

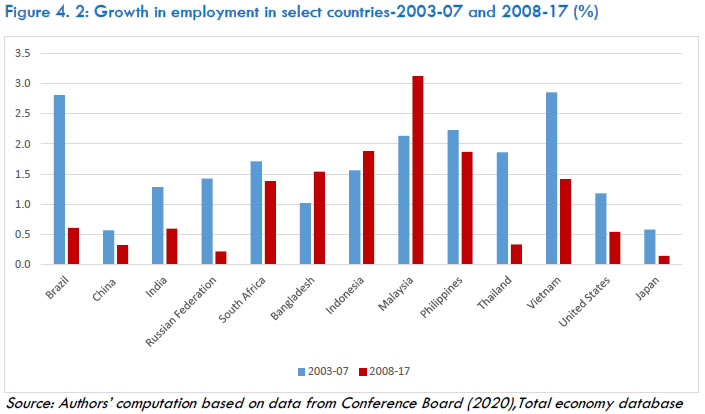

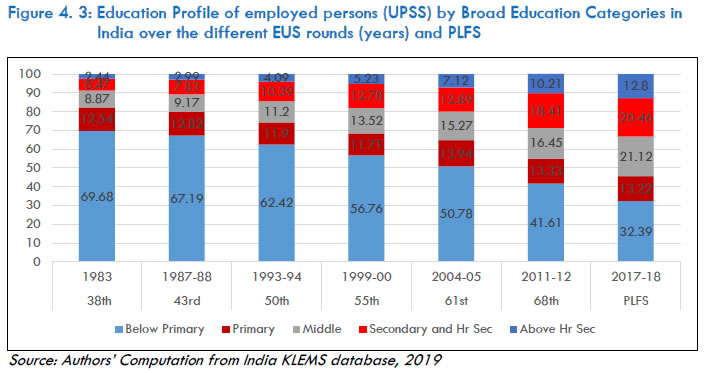

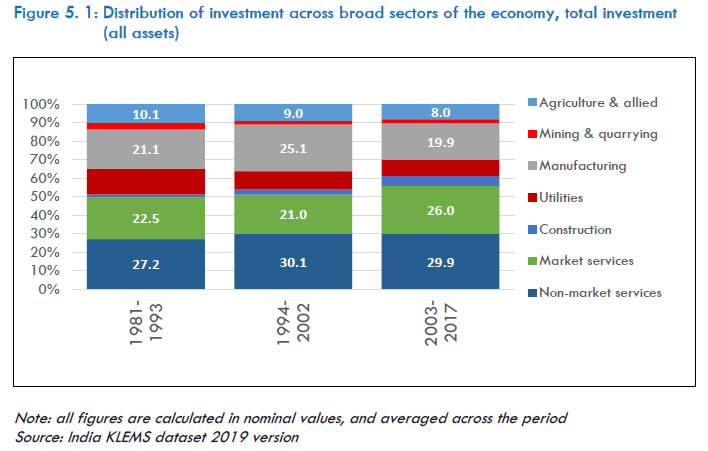

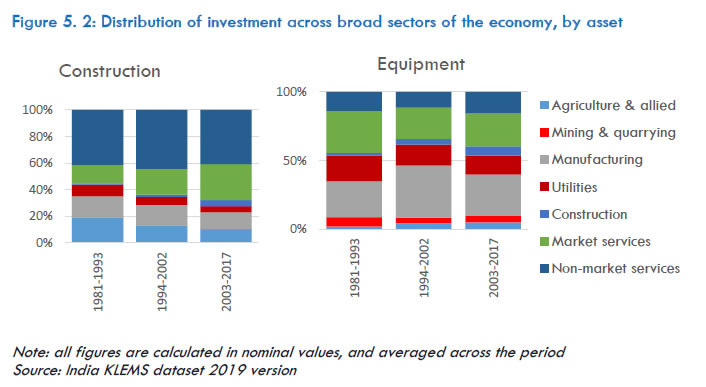

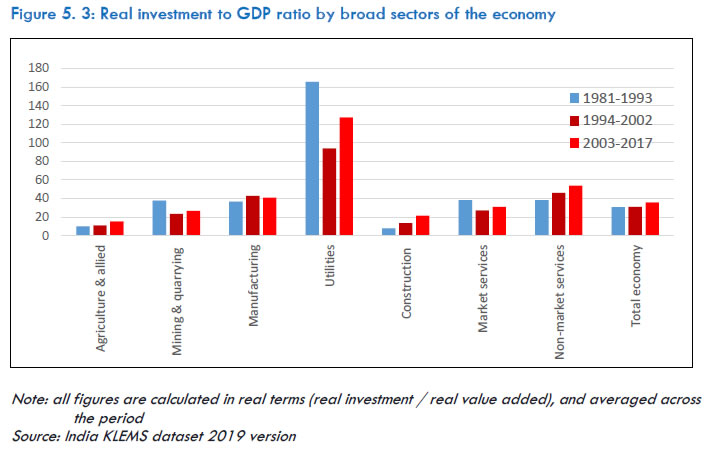

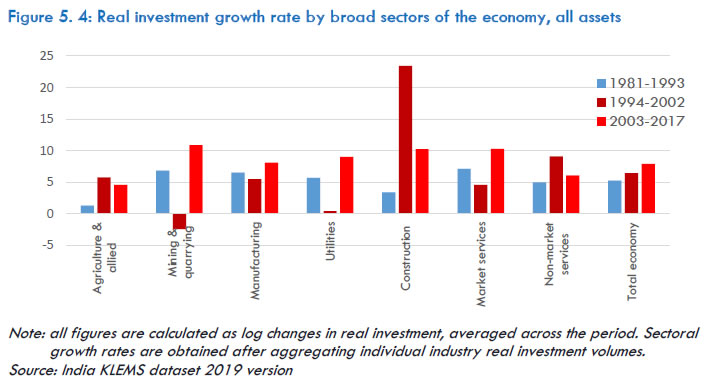

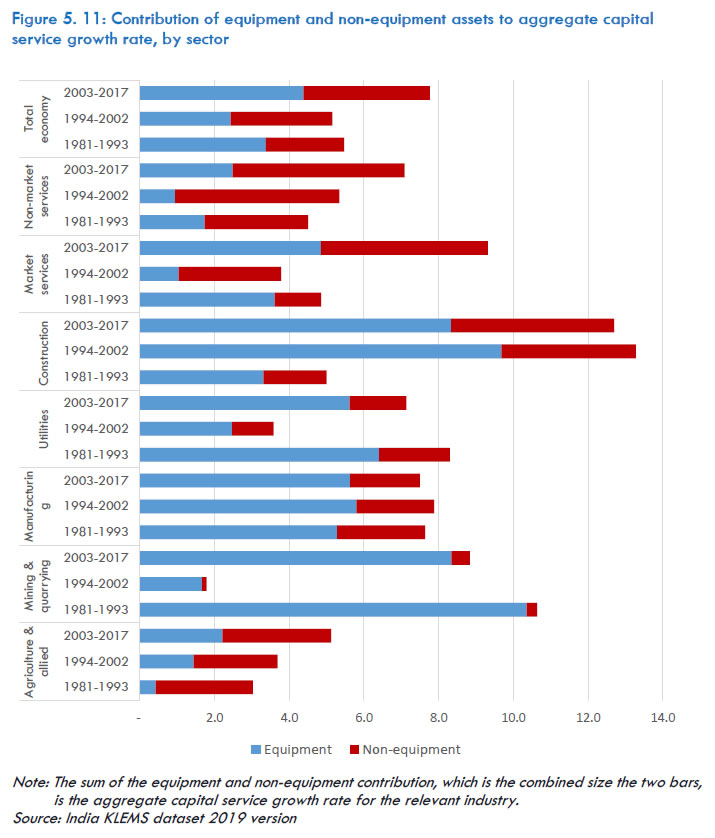

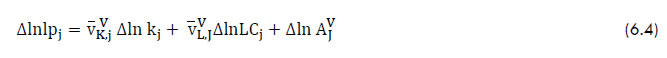

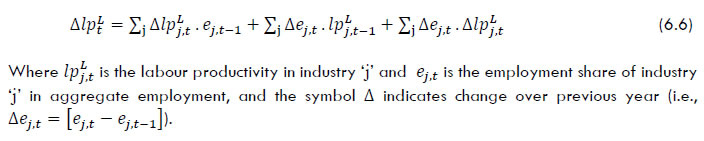

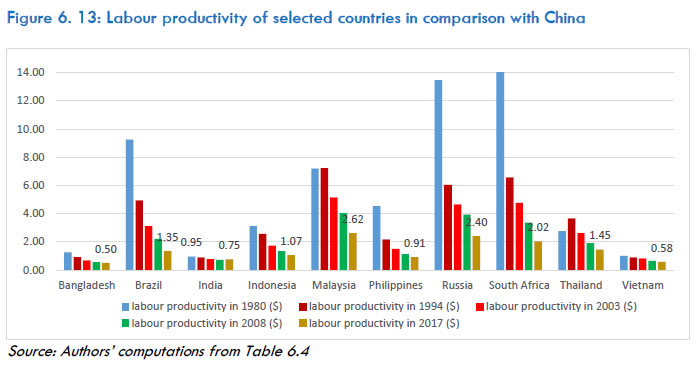

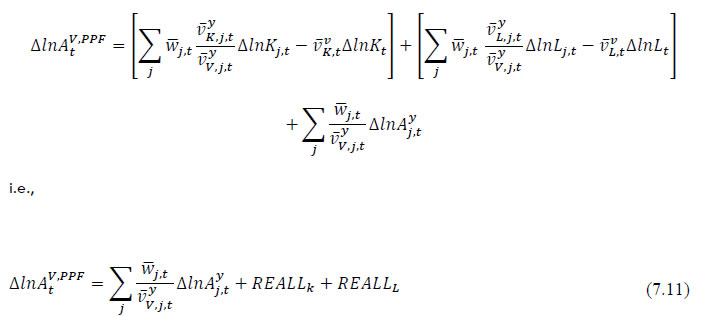

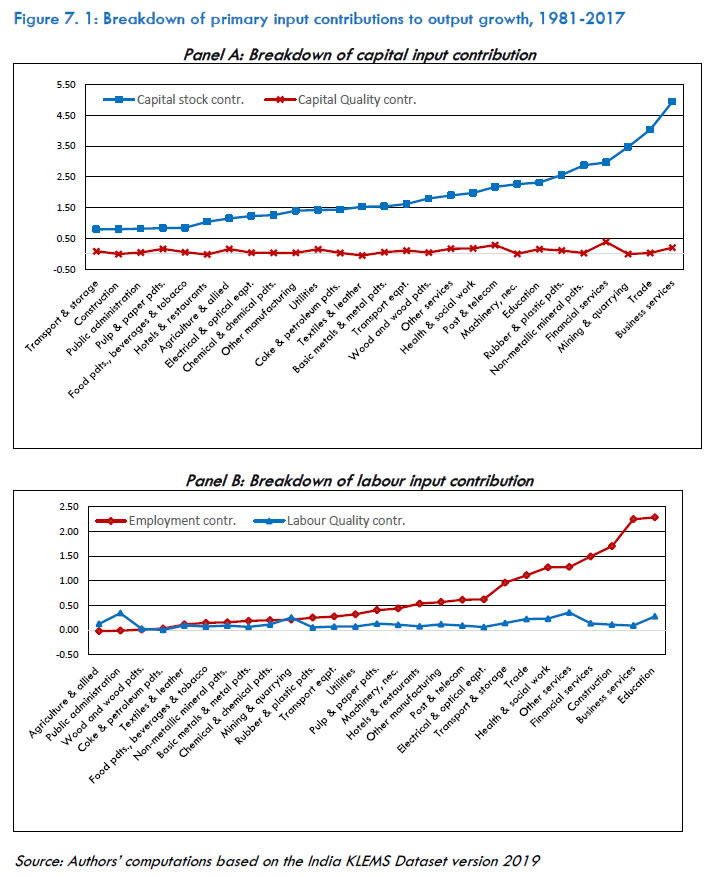

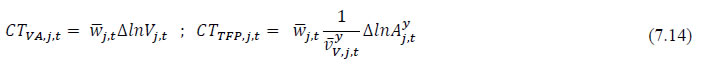

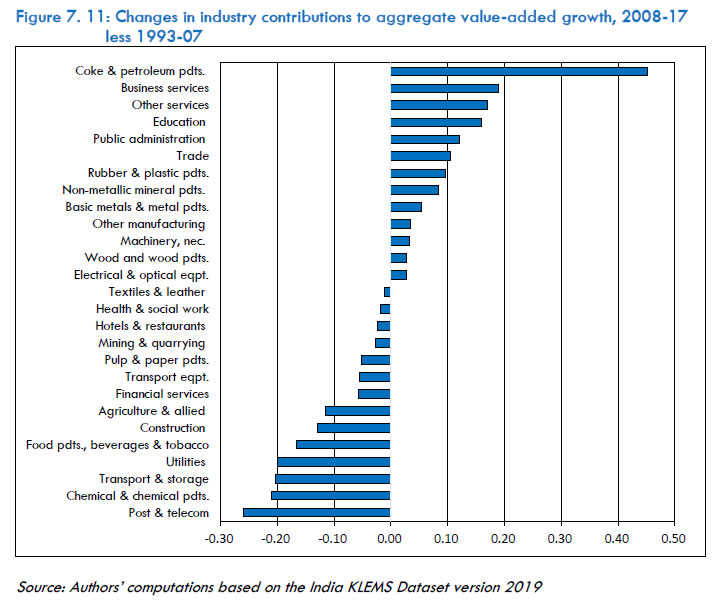

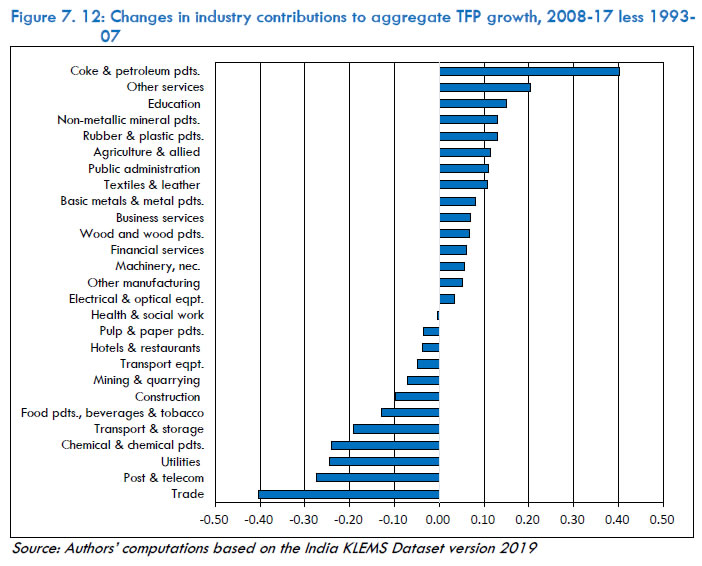

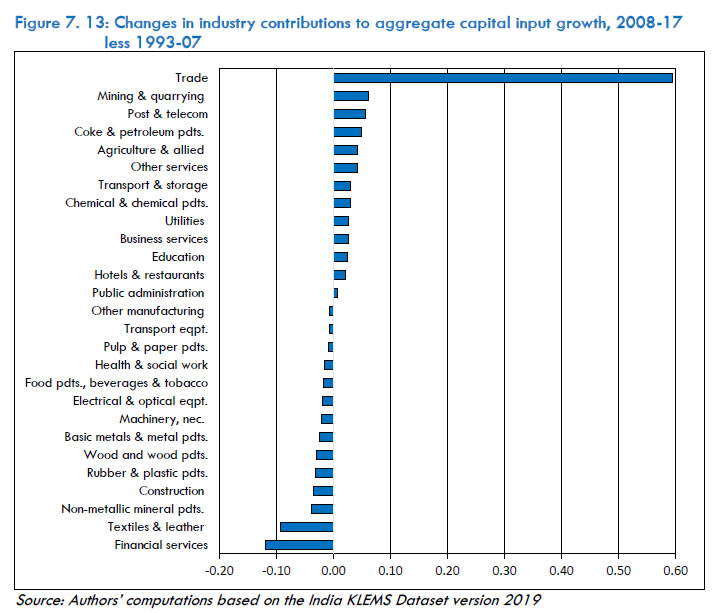

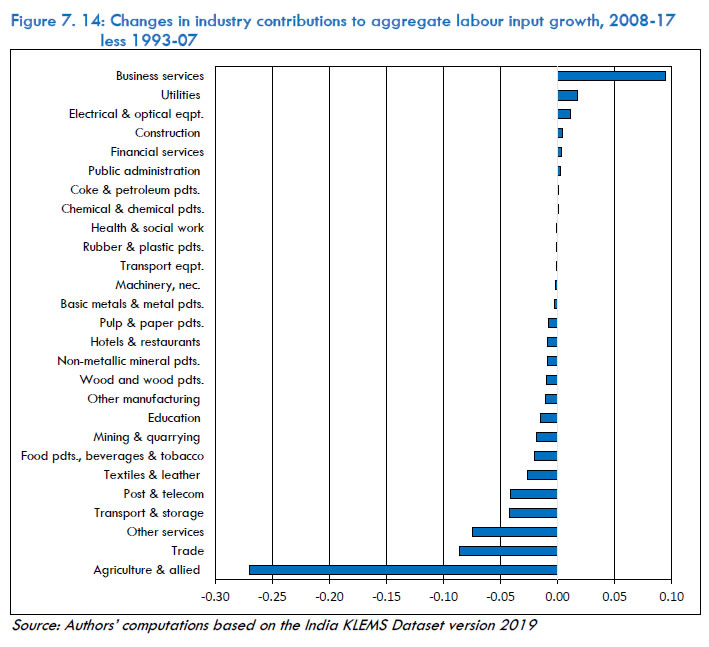

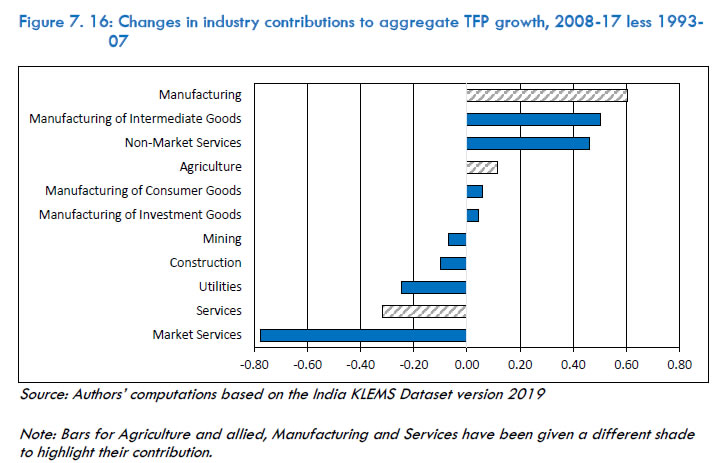

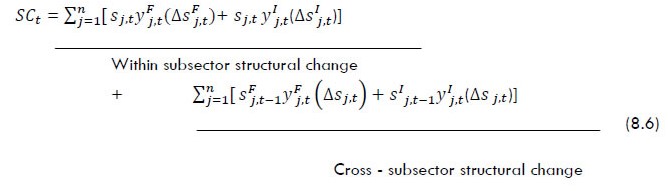

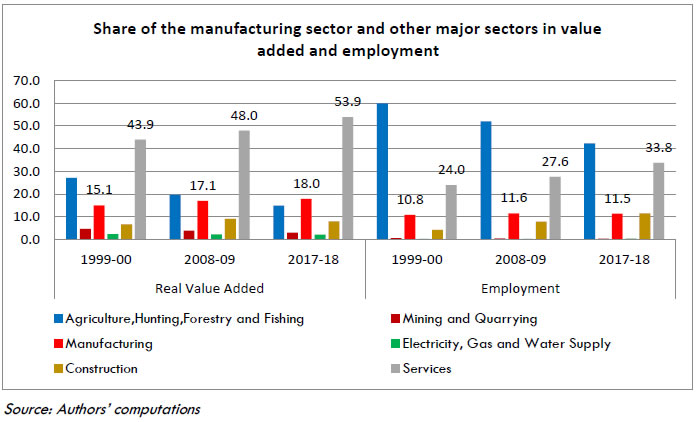

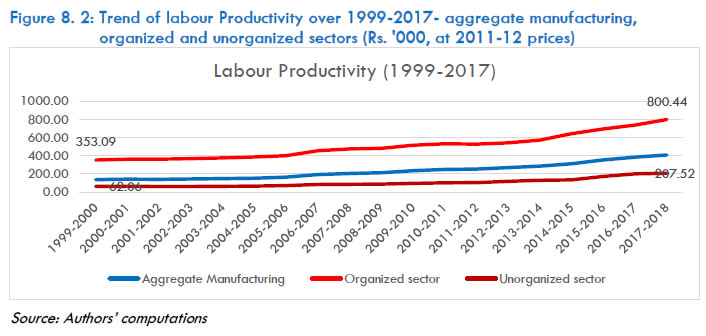

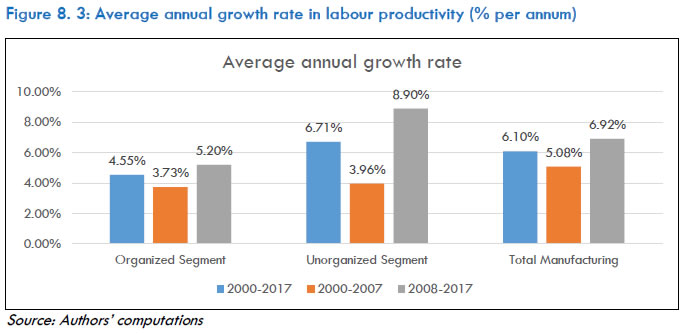

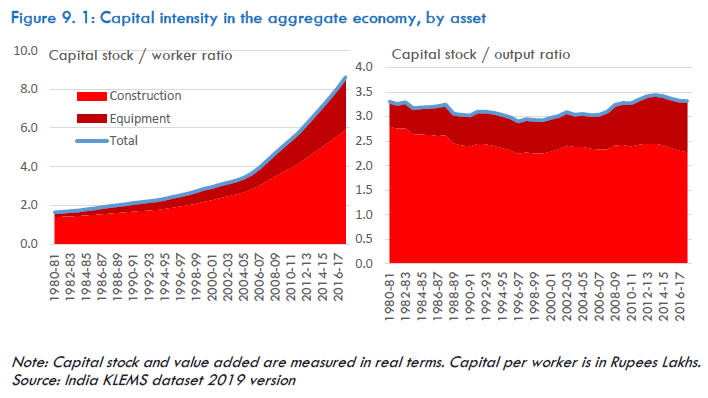

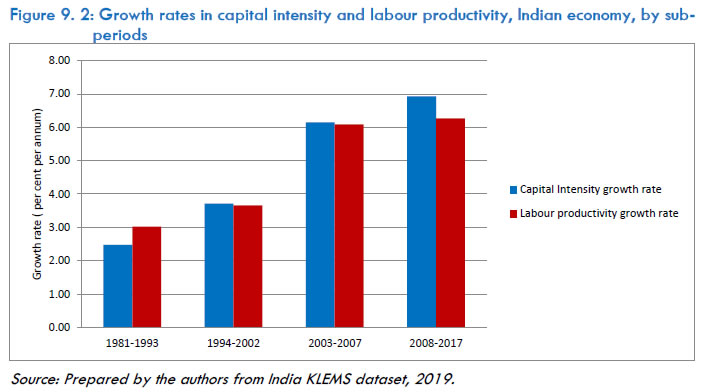

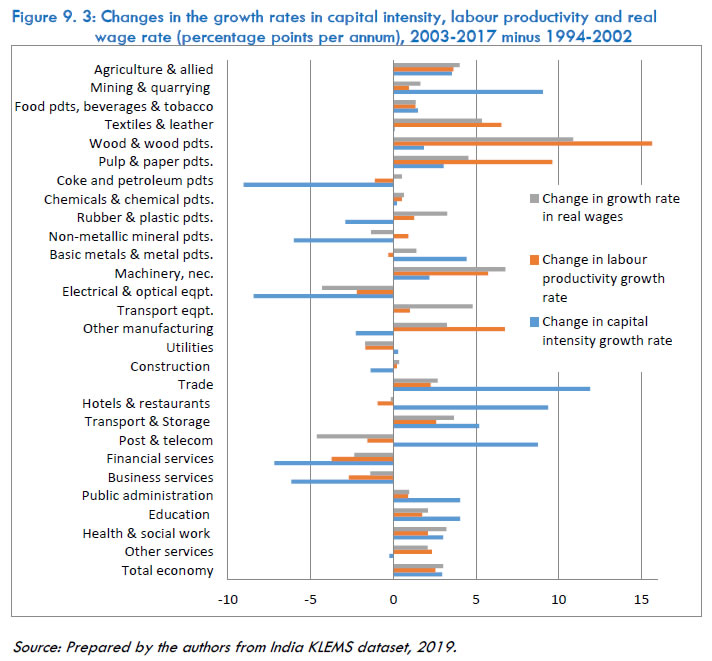

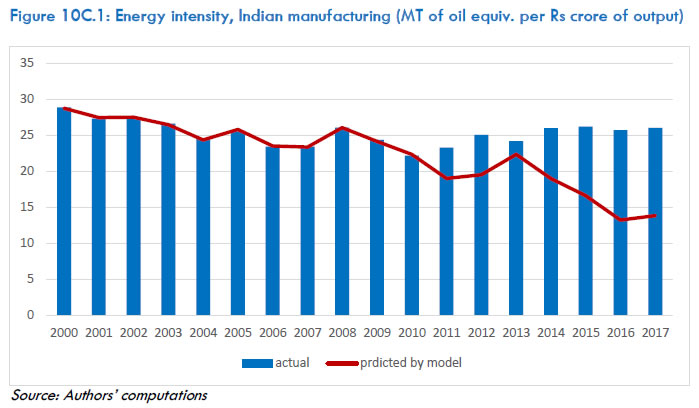

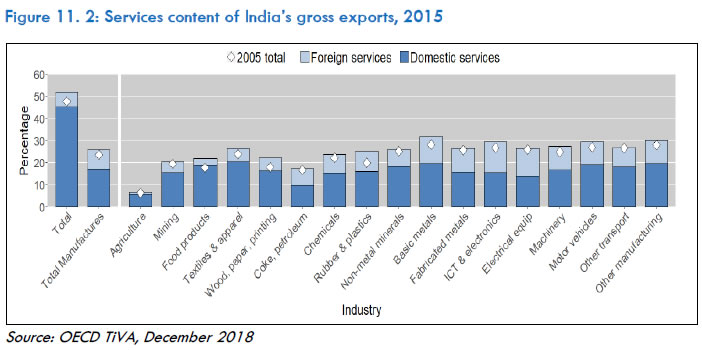

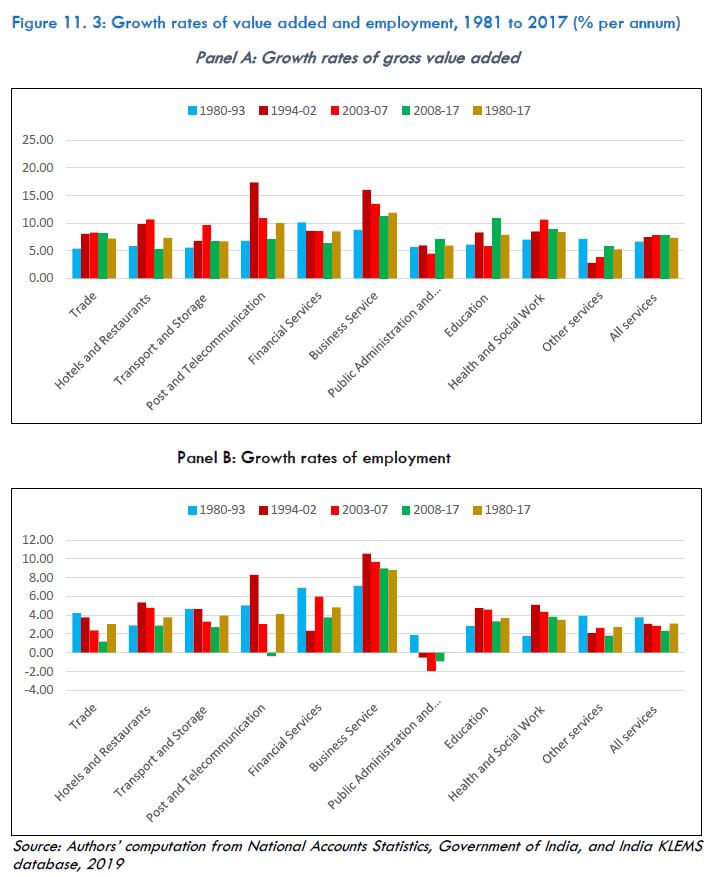

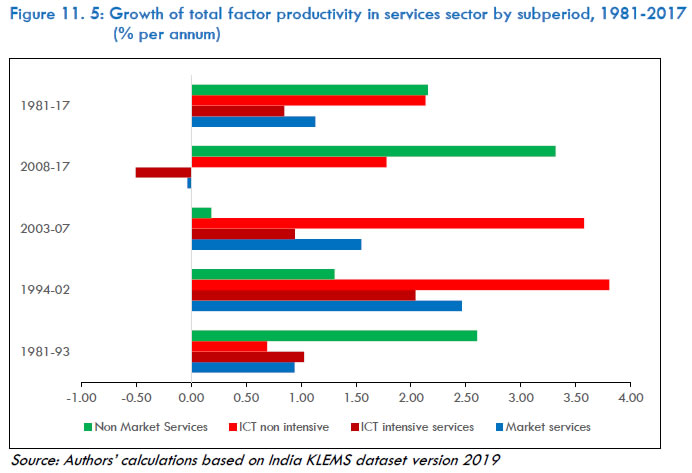

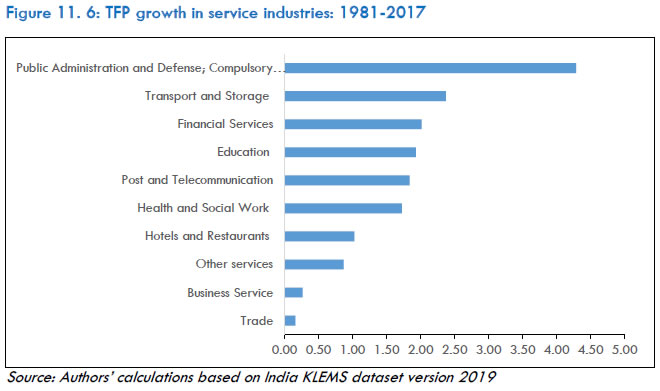

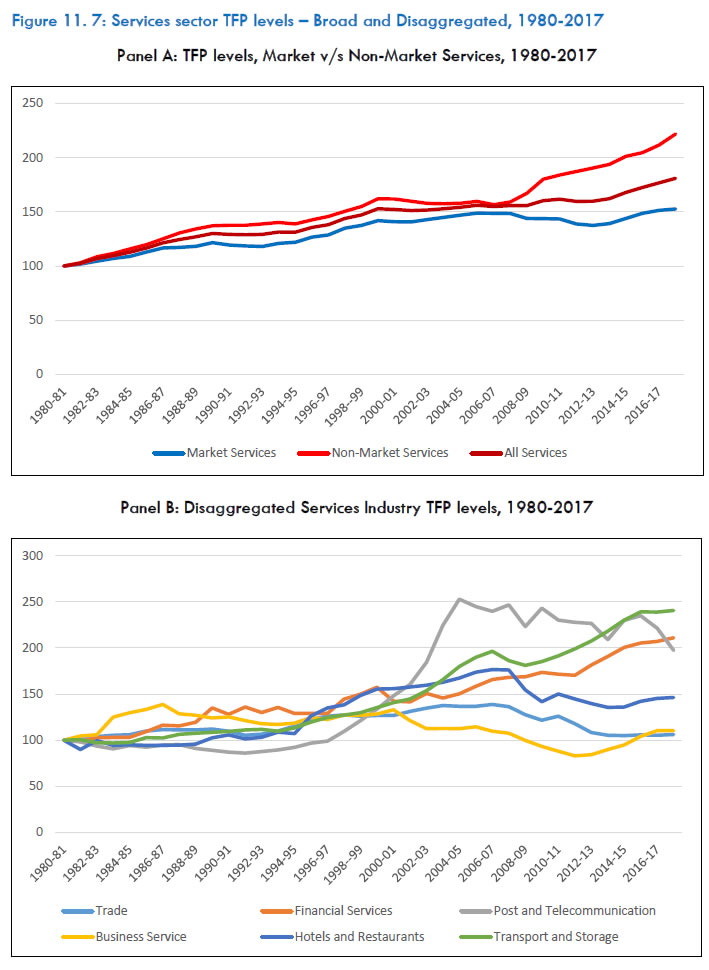

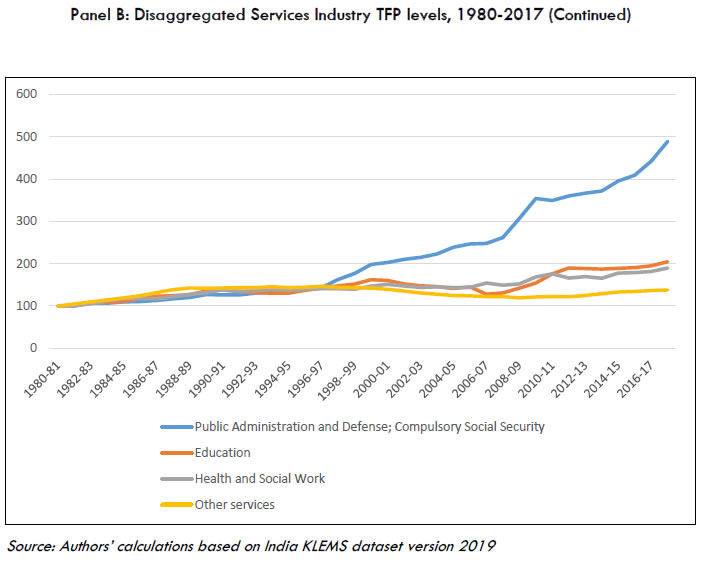

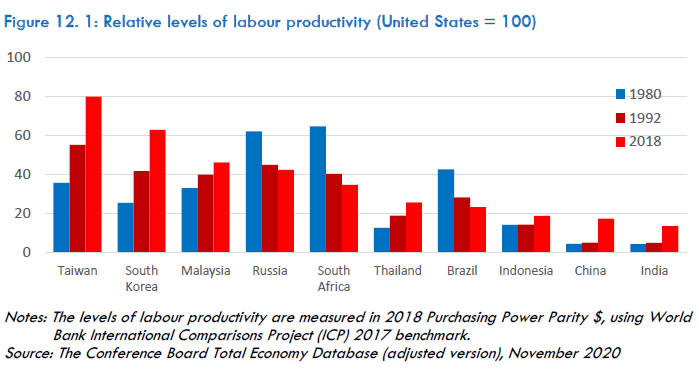

| Contents | | Foreword | | Preface and Acknowledgements | | Chapter 1: Introduction to India KLEMS Approach | | 1.1 Introduction | | 1.2 Evolution of India KLEMS Research | | 1.3 Global Productivity Research | | 1.4 Productivity research in India | | 1.4.1 Early Research | | 1.4.2 Recent Research | | 1.4.3 Productivity research based on KLEMS database | | 1.5 Report summary and contribution of chapters | | Annexure 1A: List of Industries in India KLEMS Database | | Annexure 1B: The data sources and construction of variables – key points | | Annexure 1C: Publications of the Research Team Based on India KLEMS Database | | Chapter 2: Sources and Methodology: India KLEMS Database | | 2.1 Introduction | | 2.2 Approach to measuring productivity in India KLEMS: The growth accounting methodology | | 2.2.1 The KLEMS production function | | 2.2.2 The decomposition of value added and output growth | | 2.3. Data and Variables: Construction and Approaches | | 2.3.1 Gross Output | | 2.3.2 Gross Value Added | | 2.3.3 Intermediate inputs | | 2.3.4 Labour Input | | 2.3.5 Capital Input | | 2.3.6 Labour Income Share | | 2.4 Data Challenges & Outstanding Issues | | 2.4.1 Gross Output and Intermediate Inputs | | 2.4.2 Labour Input | | 2.4.3 Labour Income Share | | 2.4.4 Capital Input | | 2.4.5 Methodology of TFP Measurement | | 2.5 Summary | | Annexure 2A: Additional Tables | | Chapter 3: Economic Growth in India: An Industry Perspective | | 3.1 Introduction | | 3.2 Changes in the structure of the economy | | 3.3 Aggregate value-added growth and industry and broad sector contributions to aggregate growth | | 3.4 Growth of industry output and intermediate inputs | | 3.5 Summary and Conclusion | | Annexure 3A: Additional Table | | Chapter 4: Employment, Labour Quality and Labour Income Share | | 4.1 Introduction | | 4.2 Profile of the Workforce since 1980-81 | | 4.3 Structure and growth in employment | | 4.3.1 Structure of employment in India during 1980-2017 | | 4.3.2 Growth in employment | | 4.4 Growth in Labour Quality Index | | 4.4.1 Growth in Labour Quality index in Broad sectors | | 4.4.2 Growth in labour quality index for the 27 India KLEMS industries | | 4.5 Growth in Labour Input | | 4.5.1 Growth in Labour Input in Broad sectors | | 4.5.2 Growth in Labour Input for the 27 KLEMS industries | | 4.6 Labour Income Share | | 4.6.1 Trends in labour income share in India | | 4.6.2 The volatility of the labour income share | | 4.6.3 Reallocation of change in the labour income share | | 4.7 Summary and Conclusion | | Annexure 4A: Additional Tables | | Annexure 4B: Trends in employment in the period 2011-2017 – assessing the impact of growth in real wages | | Chapter 5: Investment and Capital Input | | 5.1 Introduction | | 5.2 Composition and Growth of Investment | | 5.2.1 Distribution of Investment across Broad Sectors | | 5.2.2 Growth rate of real investment by broad sectors | | 5.3 Composition and growth rates of capital stock | | 5.3.1 Changing composition of capital stock | | 5.3.2 Growth rates of capital stock | | 5.4 Capital service growth rates | | 5.5 Capital composition effects | | 5.6 Summary and conclusions | | Annexure 5A: Additional Tables | | Chapter 6: Trends and drivers of labour productivity in Indian industries | | 6.1 Introduction | | 6.2: Literature on Labour Productivity | | 6.3. Methodology and Dataset | | 6.3.1 Measurement of labour productivity | | 6.3.2 Sources of Labour productivity growth | | 6.3.3 Decomposition of labour productivity- within and between effects | | 6.3.4 Data and variables | | 6.4: Labour Productivity – Trends and behaviour | | 6.4.1 Labour Productivity growth in the disaggregate industries | | 6.4.2 Changes in the growth rate of labour productivity | | 6.5 Sources of Growth in Labour Productivity and the ‘virtuous’ pattern of growth | | 6.5.1 Sources of Growth in Labour Productivity | | 6.5.2 The virtuous pattern of growth of labour productivity | | 6.6 Labour productivity at the broad sectoral level, reallocation and sectoral decomposition | | 6.6.1 Level of labour productivity in the broad sectors | | 6.6.2 Growth of labour productivity in the broad sectors | | 6.6.3 Labour Productivity: Reallocation and Sectoral Decomposition | | 6.7 A cross-country comparison of labour productivity | | 6.8 Summary and Conclusion | | Annexure 6A: Additional Table | | Chapter 7: Industry origins of Aggregate Growth and Total Factor Productivity | | 7.1 Introduction | | 7.2 Review of Indian Growth and Productivity Literature | | 7.2.1 Studies based on non-India KLEMS datasets | | 7.2.2 Studies based on the India KLEMS datasets | | 7.3 Methodology | | 7.3.1 Production Possibility Frontier (PPF) approach | | 7.3.2 Direct Aggregation across Industries | | 7.3.3 Sectoral Aggregation | | 7.4 Disaggregated Empirical Results, 1980-17 | | 7.4.1 Sources of Industry-level Output Growth | | 7.4.2 Industry Origins of Aggregate Growth and Productivity | | 7.4.3 Industry contributions to growth of aggregate primary inputs | | 7.5 Disaggregated Growth & Productivity Dynamics – Pre & Post Global Financial Crisis | | 7.5.1 Changes in sources of output growth, 2008-17 less 1993-07 | | 7.5.2 Changes in industry contributions to aggregate growth & productivity, 2008-17 less 1993-07 | | 7.5.3 Changes in industry contributions to growth of aggregate primary inputs, 2008-17 less 1993-07 | | 7.6 Sectoral Origins of Growth & Productivity | | 7.7 Summary & Conclusions | | Annexure 7A: Additional Tables | | Chapter 8: Growth, Employment and Labour Productivity in Formal and Informal Manufacturing | | 8.1 Introduction | | 8.2 Formal-Informal Divide and the Role of the Informal Sector | | 8.2.1 Formal-Informal Divide in Employment | | 8.2.2 Informality in India | | 8.3. Dataset and Methodology | | 8.3.1 Data | | 8.3.2 Methodology | | 8.4 Relative Share of the Manufacturing Sector and the Extent of Informality | | 8.4.1 Manufacturing sector | | 8.4.2 Informality in the manufacturing sector of India | | 8.5 Growth in Real GVA, Organized and Unorganized Manufacturing | | 8.6 Growth in Employment, Organized and Unorganized Manufacturing | | 8.7 Labour Productivity in the unorganized and organized sector of the Indian economy | | 8.7.1 Labour productivity – trends and behaviour | | 8.7.2 Informality: Role in stagnant growth and sectoral decomposition | | 8.7.3 Decomposition of aggregate labour productivity growth - the reallocation effect | | 8.8 Summary and Conclusion | | Annexure 8A: Construction of real GVA series for organized and unorganized segments of manufacturing industries | | Annexure 8B: Growth rate in real GVA series in organized and unorganized segments of manufacturing industries, 1981-2017 | | Annexure 8C: Growth in employment in organised and unorganised segments of manufacturing, 1981-2017 | | Chapter 9: Capital Intensity in Industries | | 9.1 Introduction | | 9.2 Trends in capital intensity | | 9.2.1 Capital intensity in the aggregate economy and broad sectors | | 9.2.2 Capital intensity in the 27 KLEMS industries | | 9.3 Growth in Capital Intensity, Labour Productivity and Real Wages | | 9.4 Wage-rental ratio and capital intensity of the Indian economy: Econometric Analysis | | 9.4.1 Relative prices of capital | | 9.4.2 Effect of Wage-rental ratio on and capital intensity – Aggregate Economy | | 9.4.3 Impact of real wage on capital intensity – estimate for manufacturing based on a panel data model | | 9.5 Conclusion | | Chapter 10: Energy Intensity in Manufacturing Industries | | 10.1 Energy intensity | | 10.1.1 Trends in energy intensity in aggregate manufacturing | | 10.1.2 Trends in energy intensity in organised manufacturing | | 10.1.3 Impact of energy prices on energy intensity in organised manufacturing | | 10.2 Determinants Energy Use and Energy Intensity in Organized Manufacturing | | 10.3 Conclusion | | Annexure 10A: Construction of energy use and energy intensity series for manufacturing | | Annexure 10B: Construction of Industry-level energy use and energy-intensity series for organized manufacturing | | Annexure 10C: ARDL Model Estimation for Explaining Energy Intensity of Manufacturing using Time-series Data at the Aggregate Manufacturing Level | | Chapter 11: Growth and Productivity in India’s Services sector | | 11.1 Introduction | | 11.2 Service Sector Liberalization: An Overview | | 11.3 Service Sector Performance: 1980-2017 | | 11.4. Productivity Trends in India’s Service Sector | | 11.5. Conclusions | | Annexure 11A: Policies Relating to Services Sector | | Chapter 12: Growth and Productivity: A China and India comparison | | 12.1 Introduction | | 12.2 Labour Productivity and growth in India and China: The aggregate picture | | 12.3 Aggregations of KLEMS industry growth rates: Methodology and data | | 12.3.1 Methodology | | 12.3.2 CIP/China KLEMS Data | | 12.4 Empirical results | | 12.4.1 Labour productivity and TFP in the broad sectors of the economy | | 12.4.2 Labour productivity and TFP in the select industry groups of the economy | | 12.4.3 The industry pattern of aggregate TFPG | | 12.4.4 Capital deepening and labour productivity growth – a comparative perspective | | 12.5 Conclusion | | Annexure 12A: India KLEMS and China KLEMS, Concordance | | Chapter 13: Summary and Conclusion | | 13.1 The context | | 13.2 Outputs and Inputs | | 13.2.1 Output, value added and intermediate inputs | | 13.2.2 Labour input and labour income share | | 13.2.3 Capital input | | 13.2.3 Capital input | | 13.3 Labour Productivity and Total Factor Productivity | | 13.4 The Performance of Manufacturing – formal-informal divide and energy use | | 13.4.1 Formal-Informal Divide | | 13.4.2 Energy intensity of manufacturing | | 13.5 Capital intensity: A relook at the trends and underlying factors | | 13.6 Services as an engine of Growth | | 13.7 Comparative performance of India and China | | 13.8 India KLEMS: The way forward | | 13.8.1 Intangible investment | | 13.8.2 ICT capital | | 13.8.3 Informal sector | | 13.8.4 Relaxing neoclassical assumptions | | 13.8.5 Productivity implications for welfare | | References |

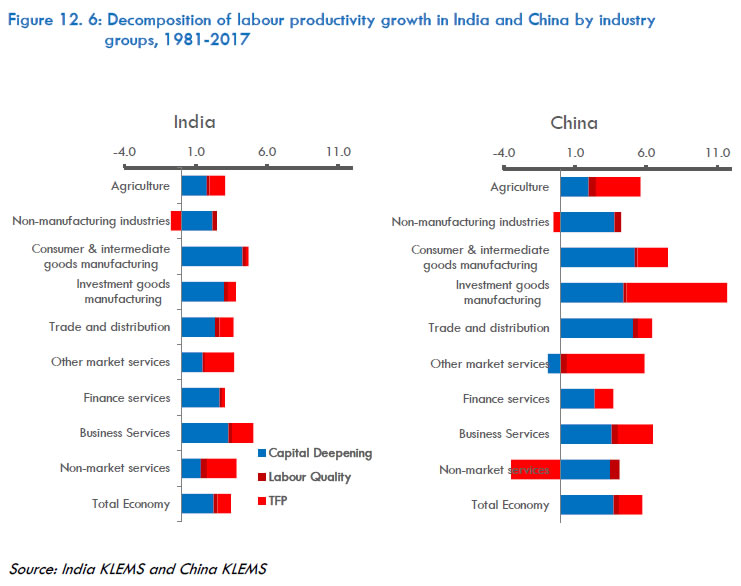

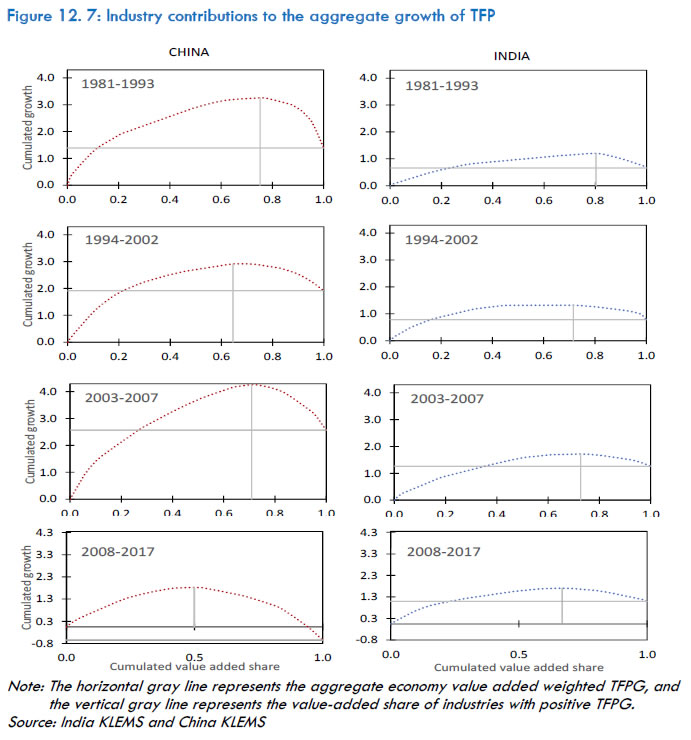

| Abbreviations | | ASI | - | Annual Survey of Industries | | CSO | - | Central Statistics Office | | EMDE | - | Emerging Market and Developing Economies | | EUS | - | Employment-Unemployment Survey | | GDP | - | Gross Domestic Product | | GFC | - | Global Financial Crisis | | GFCF | - | Gross Fixed Capital Formation | | GO | - | Gross Output | | GVA | - | Gross Value Added | | ICT | - | Information Communication Technology | | IKD | - | India KLEMS Database | | IO | - | Input-Output | | IOTT | - | Input-Output Transactions Table | | KLEMS | - | Capital-Labour-Energy-Materials-Services | | LP | - | Labour Productivity | | NAS | - | National Accounts Statistics | | NIC | - | National Industrial Classification | | NSO | - | National Statistical Office | | NSSO | - | National Sample Survey Office | | PLFS | - | Periodic Labour Force Survey | | RBI | - | Reserve Bank of India | | SUT | - | Supply Use Table | | TFP | - | Total Factor Productivity | | TFPG | - | Total Factor Productivity Growth | | WPI | - | Wholesale Price Index | | Units | | 1 Lakh = one hundred thousand | | 1 Crore= one hundred Lakh = ten Million |

Profiles of Authors K L Krishna, a Founder Member of CDE (Centre for Development Economics), at the Delhi School of Economics, has been the Principal Investigator of the RBI-funded India KLEMS Productivity Project since 2009. With post-graduate qualifications in Statistics from the University of Kerala, and the Indian Statistical Institute, Kolkata, and Ph.D. degree in Economics from the University of Chicago, he taught Econometrics and Industrial Economics for four decades and supervised around 45 Ph.D. and M.Phil. theses in a variety of fields. He served as Head of the Department of economics. and Director, Delhi School of Economics in the 1980s and 1990s. He was the Founder Managing Editor of the Journal of Quantitative Economics for one decade, and President of the Indian Econometric Society (TIES) for one term. He is a member of the TIES Trust. He was the Chairman or member of several official Committees of the Government of India. He held the position of Chairman of CESS, Hyderabad, during 2007-13, and MIDS, Chennai during 2013-20. Bishwanath Goldar is a Retired Professor of Economics of the Institute of Economic Growth, Delhi. He has an M.A. in Economics and Ph.D. from Delhi School of Economics, University of Delhi. He has been at the Institute of Economic Growth from 1979 to 2014, except for three brief stints at a professorial or equivalent position at the National Institute of Public Finance and Policy (1988-90), the Indian Council for Research on International Economic Relations (2003-04), and the Jawaharlal Nehru University (2012-13). During 2015-2016 he was a National Fellow of the Indian Council of Social Science Research, affiliated with the Institute of Economic Growth. He is a former member of the National Statistical Commission and is currently a member of the Standing Committee on Economic Statistics, constituted by the Ministry of Statistics and Programme Implementation, Government of India. His area of specialization is industrial economics and international trade. The bulk of his research has been on productivity and employment in Indian Industries, wage share in value added, and price-cost margin in Indian manufacturing, export performance of Industrial firms, effective protection of Indian industries, impact of trade reforms on the performance of industrial firms, and foreign direct investment in India. He has also undertaken studies on rural water supply in India and Bangladesh, water supply in Delhi, pollution of river water and river water quality in India, and the environmental aspects of Indian industries including studies on energy efficiency in Indian industrial firms and the impact of environmental performance of industrial firms on their stock prices. Deb Kusum Das, Professor at the Department of Economics, Ramjas College. He has a PhD from the Delhi School of Economics and received the EXIM Bank IEDRA Award 2004 for his doctoral dissertation, “Some Aspects of Productivity and Trade in Indian Industry”. He is also associated with ICRIER as an external researcher and researched on important issues related to Indian economy: jobs, labour intensive manufacturing, India’s global competitiveness. His research interests are empirical international trade, labour markets and productivity growth of the Indian economy. He is the co-founder of a network for South Asian undergraduate students of Economics (SAESM). Suresh Chand Aggarwal is currently the Senior Fellow, ICSSR at Department of Business Economics. Earlier retired as Head and Professor from the Department of Business Economics (now known as Department of Finance and Business Economics), University of Delhi. He has guided a number of students for their Ph.D. and M.Phil. thesis. He does research in Labour Economics, Econometrics and Development Economics and has published a number of papers in the related areas in national and international Journals. He has been associated as a Lead researcher on Labour in the India KLEMS project from its beginning and participated in numerous national and international conferences and has contributed to a number of papers under the KLEMS project. He has earlier done projects and consultancies for many organizations, e.g., ILO, World bank, UGC, ICRIER, etc. His current projects are RBI funded 'INDIA KLEMS' Project, and ICSSR funded ‘Inclusive Growth Project’. Abdul Erumban teaches and researches at the University of Groningen (RuG), Groningen, The Netherlands. He is also a senior research fellow at the Conference Board (TCB) and an academic member of the Productivity Institute at the Alliance Manchester Business School. During 2013-2019, he worked as a senior economist at TCB, leading their research on global productivity, global economic outlook, and emerging markets. He has an M.A. in Development Economics from John Matthai Centre, University of Calicut, an M.Phil in Applied Economics from the Centre for Development Studies, and a Ph.D. in Economics from the University of Groningen. His research centers on productivity, technological change, structural change, digital transformation and its impact, globalization, global value chain, and international comparisons of economic development. He maintains a particular interest in economic issues in emerging markets, particularly India, China, and the Middle East economies. Being an active participant in the KLEMS research initiatives aimed to understand productivity dynamics in the world's major economies, he sustains a good relationship with international networks on productivity research. He is an advisor to the Asia KLEMS, which aims to understand productivity dynamics in Asian economies, and a lead researcher on capital in the Reserve Bank of India's India KLEMS project, seeking to understand productivity and competitiveness in Indian industries. He has also actively participated in European Commission's World Input-Output Database project at the University of Groningen. His principal publications are in the Journal of Economic Perspectives, Review of Income and Wealth, Journal of Comparative Economics, Industrial and Corporate Change, and Structural Change and Economic Dynamics. Pilu Chandra Das is an Assistant Professor in the department of economics at Kidderpore College, University of Calcutta. He has an M.A. in economics and M.Phil. from Delhi School of Economics, University of Delhi. His M.Phil. thesis was on “Total Factor Productivity in Indian Organised Manufacturing: the story of the Noughties”, dealing with productivity in Indian registered manufacturing sector. He has been associated with the India KLEMS project since 2012. His research interest is mostly in productivity and has been a co-author of several papers prepared under the India KLEMS project. He has several published papers. Earlier, he was associated with ICRIER as a research assistant in a project named ‘Estimating Domestic Value Added and Foreign Content in India’s Exports’ sponsored by the Department of Economic Affairs, Ministry of Finance, Government of India. He was also associated with National University of Singapore in constructing the variables for the Singapore KLEMS data set.

Foreword The innovative work of the India KLEMS team has resulted in the groundbreaking India Productivity Report, which is a comprehensive report primarily using the India KLEMS database to examine various aspects of productivity dynamics in Indian industries. The India KLEMS project, which follows the standards of World KLEMS and EU KLEMS, provides a database on capital, labour, and intermediate inputs along with total factor productivity, thus facilitating a comparison of India's productivity dynamics with other global players. It is an important step in analyzing the role of factor accumulation, productivity, and structural change in the Indian economy. The India KLEMS project came to fruition in 2009 with Prof. KL Krishna as chairperson. I have known Krishna since he received his PhD from the University of Chicago in 1967, after completing his dissertation on productivity and then returning to DSE at the University of Delhi. Krishna has been the ideal lead on this project. From the inception of the project, Prof. Bishwanath Goldar served as advisor and the late Deb Kusum Das served as the coordinator. Prof. Suresh Chand Aggarwal and Dr. Abdul Azeez Erumban were among the original project team. Most-recently, Pilu Chandra Das joined the team in 2015. They, along with numerous collaborators, have made an outstanding contribution with the publication of the India Productivity Report. The Report was more than a decade-long endeavor, during which time numerous articles have been published in international journals by the team. The India KLEMS team has attended and presented at all World KLEMS conferences, starting in 2010, and all Asia KLEMS meetings starting in 2011. The India team will host the next Asia KLEMS meeting in 2022. As in many other Asian economies, overcoming the legacies of past policies has been a major challenge for India. India had adopted the path of an inward-oriented closed economy policy atmosphere since it embarked on its path of planned industrialization in the mid-1950s. Since the mid-1980s, there has been some rethinking in the policy circles. Liberalization of the Indian economy to private and foreign investors began in 1988, which led to a foreign exchange crisis and IMF program in 1991. Manmohan Singh was appointed Finance Minister in July 1991, during which time India undertook bold steps to reform the economy. This changed the economic development path in the country, eventually giving India a more prominent and visible presence in the global economy. The pro-market policy changes have altered the business climate for the private and external sectors, making the importance of productivity growth more significant in the Indian context. While many researchers have explored the productivity dynamics in India, their work was confined mostly to the formal manufacturing sector, which had relatively better data. The constraints on data for inputs and output at the detailed industry level made it difficult to produce a fair analysis of factor inputs and productivity in other sectors of the economy. A country’s economic policies and investment climate are key components of factor accumulation and productivity, which drive economic growth. Therefore, understanding sources of economic growth is paramount to researchers and policymakers. In today’s market-oriented economy, productivity growth is as important to fostering economic growth in India as it is in raising the living standards of millions of people in the world's second most populated country. Moreover, analysis of changes in factor inputs and productivity at the industry level is essential in identifying India's growth path to facilitate a pro-growth structural transformation. Evidence suggests consistent decline in poverty over the years in India. However, as home to the world's young population, India has vast human capital potential, if tapped properly. Additionally, market opportunities for investors, along with its resources, provide the potential to improve India's living standards. Productivity plays a key role in this process by improving production efficiency and helping generate surplus for additional consumption and investment. Overcoming productivity growth challenges requires a better understanding of the underlying features of productivity of specific industries. Since the 1990s, intensified global integration as well as global fragmented production chains have resulted in drastic changes in the global economy. This has created opportunities for many developing economies, including India, to participate in segments of the global value chain, where they have a comparative advantage, and further climb up the quality ladder. Increased productivity would help better position India in the global value chain and fend off the intense competition from imports which displaces domestic producers. It is this perspective that gives the India KLEMS project and the India Productivity Report added significance. The Report also documents the changes in the employment structure of the economy, which features a fall in agriculture – as one would expect – but stagnant manufacturing. The Report has noted the recent fall in manufacturing jobs in India and the failure of the sector to absorb workers who leave the primary sector. While overall employment growth has been relatively weak, there has been a shift in the structure towards service sector jobs. Along with the need to create manufacturing jobs, the Report analyzes energy intensity to reveal the need for policy implementation that encourages energy conservation in the manufacturing sector. Policy adjustments are also recommended to enhance India's human capital. While improvements are being made, the pace must accelerate given the size of the population and labour force. Meanwhile, the agricultural sector remains the largest job-providing broad sector in India although its relative importance in job creation is declining. By developing future extensions of the KLEMS data, researchers may gain an understanding of dynamics within the sector by considering sub-sectors within the agricultural sector. Undoubtedly, the India KLEMS database and the productivity report demonstrate substantial improvements in the data and analysis of the Indian economy. The continued work on the data will lend itself to fewer assumptions. Currently, in addition to several comparability issues across various employment surveys, the researchers needed to make assumptions to fill in the gaps between survey years, as there are no comprehensive official time-series estimates available. With the liberalization of the economy in the 1990s the country became attractive to domestic and foreign investors, but hurdles still exist, namely stimulating investments in the formal sectors such as the much-important manufacturing sector. According to the Report the investment to GDP ratio in India has recently fallen. The need for reforming the labour market, improving infrastructure – both physical and human – and investment climate, are essential to stimulate investment and productivity. Although India is an excellent exporter of IT professionals and services, previous research by the India KLEMS team indicated a tremendous untapped potential in many sectors of the economy from the use of ICT, through investing in IT equipment, software, and communication. Taking into consideration various policy reforms, the trends in productivity demonstrate that productivity benefits from outward-oriented policies rather than inward-oriented ones. The India Productivity Report, as well as the India KLEMS data, have a profound impact not just on India, but on the global economy. The Report does a phenomenal job of unveiling productivity dynamics in India, which creates a clearer understanding of the growth process in the country. The India KLEMS data is a crucial tool for researchers to more intensely study and understand various aspects of India's economic growth in the coming years. Moreover, the database can serve as an invaluable resource for policymakers. Globally, the KLEMS research has advanced further to incorporate the roles of ICT and intangibles in the growth process. As the KLEMS research continues, focusing on the participation of several industries in the global value chain and the potential for specializing in specific tasks and sectors will impact India research. I look forward to the policies and research that will result from this report, as well as further development of the data. This research was made possible by the generous support of the Reserve Bank of India. For almost 13 years, RBI has funded the work on India KLEMS at the Indian Council for Research on International Economic Relations, and the Centre for Development Economics at the Delhi School of Economics. This level of support has been instrumental in building India KLEMS and the data that through continued policy and research will impact the global economy. In closing, I would like to offer my profound appreciation for the work of the late Deb Kusum Das. His role leading the India KLEMS initiative was key in bringing this publication to fruition. His focus on quantifying trade barriers in India and the impact of the economic liberalization helped drive the research of the entire group. Applause to the India KLEMS team and sincere gratitude to D.K.D. At the time of his passing, he was serving as the President of Asia KLEMS, where his passion for his work was impactful. I, along with his many friends and colleagues, will be forever grateful for his contribution to the economic community. Dale W. Jorgenson University Research Professor, Harvard University

Preface and Acknowledgements This report, titled “India Productivity Report” is based on research work carried out under the India KLEMS project at the Centre for Development Economics (CDE), Delhi School of Economics (DSE) in collaboration with the Reserve Bank of India (RBI). We, the team members of the research project, prepare this preface and acknowledgements to the report with a deep sense of grief because of the sudden and untimely passing away of Prof. Deb Kusum Das on the Christmas eve of 2021. Prof. Das has been a prominent member of the research team. He is the person who brought us into the research team. This report marking the culmination of the research project has been his dream undertaking. He played a pivotal role in the endeavour to prepare this report, from conceptualizing the content of different chapters at the early stage, to ensuring that the chapters get written in time, to getting the chapters copy edited as the work progressed, and even to attending to nitty-gritties such as the colours of lines and bars in the graphs placed in different chapters as the work had come almost to an end. The team members gratefully acknowledge the amount of work Prof Deb Kusum Das had done for the preparation of the report till the cruel hands of destiny took him away, and they have now collectively taken over the responsibility to ensure that the report be of high quality, as envisioned by Prof. Deb Kusum Das. As said earlier, the India KLEMS research project is housed at the Centre for Development Economics (CDE), Delhi School of Economics (DSE). The research project has been there from 2014. Prof. K.L. Krishna led the research project. Prof. Bishwanath Goldar acted as research advisor. Other senior members of the team that carried out research work under the India KLEMS project are Prof. Deb Kusum Das who acted as the project coordinator, Prof. Suresh Chand Aggarwal, Dr Abdul Azeez Erumban, and Shri Pilu Chandra Das. Dr Erumban is at the Groningen Growth and Development Centre, University of Groningen, the Netherlands. The research team is thankful to the Groningen Growth and Development Centre, University of Groningen for the research time Dr Erumban has devoted to the project. The project team has received ample guidance from a Research Advisory Committee whose members include the leading international experts on measurement of productivity, the most prominent of them being Prof. Dale Jorgenson of Harvard University, Cambridge MA, USA. Other experts in the advisory committee who provided direction to the research done in the project include Prof. Marcel Timmer, Prof. Bart van Ark, and Prof. Mary O’Mahony. The team will fail in its duty if it does not place on record the encouragement that they have received from the international KLEMS research community. Special thanks are due to Prof. Hak Kil Pyo, Prof. Kyoji Fukao and Prof. Harry Wu for the interaction that the team members had with them in connection with Asia KLEMS, particularly in attending meetings and conferences of Asia KLEMS. Prof Wu has been very kind to the India KLEMS research team. He has provided data and has actively participated in the studies undertaken on India-China productivity comparison. The India KLEMS research team is grateful to Prof Wu for immense helpfulness and intellectual engagement. The India KLEMS project first started at Indian Council for Research on International Economic Relations (ICRIER) in 2009, where the foundations of the subsequent research work was laid. Prior to that, a feasibility report for construction of data series on output and inputs of different sectors of Indian economy and carrying out research based on those data, similar in spirit and design to EU-KLEMS, was prepared by Prof. K.L. Krishna, Prof. Arup Mitra and Prof. Bishwanath Goldar. The feasibility report provided the basis for the development of a research proposal which was submitted to the RBI. This met with a positive response and the RBI very kindly funded the project from its inception. The first phase of the research project continued in ICRIER till 2013. Later in 2014, the new phase of the project began at CDE, DSE. The National Statistical Office (NSO) had provided a great deal of support in the form of data and technical advice when the project was at ICRIER, and they have provided such valuable support and advice also later when the new phase of the project began and continued at CDE, DSE. A series of consultation workshops were held at ICRIER in the initial phase of the research project. This was done for developing the methodologies for the measurement of inputs, output and productivity, and further refinements were made in the meetings and annual workshops held at CDE, DSE. A large number of scholars and experts, and persons with substantial knowledge of the data particularly India’s national accounts have contributed majorly in the ten odd years’ journey of the project. It is difficult to name all of them. To take a few names out of the long list, the research team members gratefully acknowledge that they have immensely benefited in the course of last 14 years of work on the project from the intellectual inputs received from Prof. T.N. Srinivasan, Prof. Isher Judge Ahluwalia, Prof. K. Sundaram, Dr Pronab Sen, Prof. T.C.A. Anant, Prof. T.S. Papola, Prof. Ashok Gulati, Prof. Simrit Kaur, Prof. Surender Kumar, Prof. Ravindra Dholakia, Prof. Pushpa Trivedi, Mr Ramesh Kolli, Mr. G. Raveendran, Mr. Bimal Giri, Mr Nilachal Ray, Dr G.C. Manna and Shri Ashish Kumar. The National Accounts Division of the National Statistical Office (NSO) has provided a great deal of support to the research project both when it was at ICRIER and when it got relocated at CDE, DSE. The support has been in the form of data and technical advice. Indeed, some unpublished data on the asset composition of investment in different industries for different years has been a major, invaluable help in the preparation of capital input series. For this support regarding capital series and in general about output and input series, the research team thanks Mr S.V. Ramanamurthy, Mr P.C. Mohanan, Mr. P.C. Nirala, Ms. T. Rajeshawari, and Ms. Anindita Sinharoy. Mr Ramanamurthy has been attending the coordination committee meetings and advisory committee meetings and has contributed to the project through his advice. Interaction with officers of RBI has been of immense benefit to the research project. In the presentations made at the Mumbai Office of RBI in 2011 and 2012, considerable insights were obtained from the comments and suggestions received from Late Dr Subir Gokarn (Deputy Governor, RBI) and Shri Deepak Mohanty (Executive Director, RBI). Subsequently, in July 2018, the research team got an opportunity to make a presentation of their research findings at a workshop at the Mumbai Office of the RBI. Dr Viral Acharya (Deputy Governor, RBI) gave the introductory observations and chaired one of the sessions of the workshop, and Dr Amartya Lahiri contributed to the workshop with his comments and suggestions. The comments and suggestion received at the workshop were a great help to the research. The team wishes to thank particularly Prof. T.C.A. Anant, Prof. Pami Dua, Prof. Chetan Ghate, Prof. K. Narayanan, and Prof. Pushpa Trivedi. In the course of that workshop, several RBI officers made presentations based on their research, which provided useful intellectual inputs for the research undertaken by the India KLEMS team. Over the last seven years, since the second phase of the project started at CDE, DSE from 2014, the India KLEMS research team had the benefit of interacting with RBI officials in the co-ordination committee meetings, advisory committee meetings, and at the annual workshops where the research undertaken during the year was presented. There is a long list of RBI officers to whom the India KLEMS team is indebted for intellectual inputs and ideas that they have provided in such meetings. The presentations made by RBI officers at the annual workshops held under the research project have been a matter of great encouragement to the India KLEMS research team. The research team wishes particularly to thank Dr. Rajeev Ranjan, Ms. Balbir Kaur, Ms. Rekha Mishra, Dr. Jai Chander, and Mr. S.V. Arunachalam for the support, encouragement and constructive suggestions in the coordination meetings and advisory committee meetings. Other RBI officers that the India KLEMS research teams wish to thank sincerely include Shri B. M. Misra, Dr Satyananda Sahoo, Ms. Rigzen Yangdol and Mr Avdhesh Kumar Shukla. The Indian KLEMS research team thanks the RBI officers who made presentations of their research at the annual workshops of the KLEMS project held at DSE. To name some of them, these include Shri Sarthak Gulati, Shri Utsav Saksena, Shri Avdhesh Shukla, Ms. V. Dhanya, Mr. Sonna Thangzason, Ms. Sonam Choudhury, Shri Rajib Das, Shri Siddhartha Nath, Dr. Harendra Behra and Shri Saurabh Sharma. In addition, for chairing the sessions of the annual workshops, the India KLEMS team would like to thank Dr M.D. Patra and Dr Rajeev Ranjan. In the course of last two years, the India KLEMS research team has been interacting with several senior officers of RBI, Dr M. D. Patra, Dr Sitikantha Pattanaik, Dr D. P. Rath, and Dr Rajiv Ranjan for the coordination of the project. The team is sincerely thankful to them. The team would like to thank Mr. Avdhesh Kumar Shukla for the interactions it had with him in the course of meetings and annual workshops. During 2021, training programs for RBI officers were held for the purpose of skill transfer, so that after 2021, the project could be housed at the RBI, implemented by the RBI officers. The India KLEMS research team greatly appreciates the efforts made towards learning and interest shown in the training programs by Dr Sadhan Chattopadhyay, Shri Siddhartha Nath, and Dr Sreerupa Sengupta. The annual workshops under the KLEMS project gave an opportunity to interact with other researchers working in the area of productivity in India. For making presentations at the workshops and for participation in the discussions, thanks are due to Prof. Dibyendu Maiti, Dr Jagganath Mallick, Ms. Niti Khandelwal, and Ms Rupika Khanna. The India KLEMS research team is grateful to Dr Rakesh Mohan who was the Director of ICRIER when the research proposal and the request for grant was given to the RBI. For providing ample encouragement and for helping in administrative matters, thanks are due to the successive Directors of ICRIER during 2009-2013 when the research project was housed at ICRIER, Dr Rajeev Kumar, Dr Parthasarathi Shome, and Dr Rajat Kathuria, and to the successive Executive Directors of CDE, Prof. Sunil Kanwar Prof J.V. Meenakshi, , Prof. Rohini Somanathan, Prof. Shreekant Gupta, Prof. Aditya Bhattacharjea, and Prof. Dibyendu Maiti in the course of last eight years when the project was housed at CDE. The ICRIER staff and CDE staff have been always helpful in the implementation of the research project, for which the research team wish to record their appreciation and thanks. Among the ICRIER staff, the KLEMS research team are especially thankful to Shri Manmeet Ahuja and Mr Krishan Kumar, who along with their team members provided considerable help in organizing workshops, co-ordination committee meetings, and other meetings connected with research work. The research team particularly wants to thank Mr Surjit Singh, Manager of CDE during the first five years of the project at CDE, 2014 to 2018, and Ms Deepika Garg, who has been the Manager of CDE since 2019. The research team wishes to thank Shri Rajesh Papnai who maintains accounts, the ICT personnel over the years, Mr. Sanjeev Sharma, Ms. Mandeep Kaur, Mr. Raju Chauhan, Mr. Sonveer Vats and Mr. Rohit Kohli, for the ICT related support they have provided, and other subordinate staff, Mr. Mritunjay Bisht and Mr. Ashok Kumar for making arrangements in connection with meetings and workshops. The research work under the India KLEMS project involved a massive amount of work for data collection and processing. This would not have been possible without the support received from other members of the research team, which is gratefully acknowledged. In the course of the initial four years of the project at ICRIER valuable research work has been done and support provided by Ms Kuehlika De, Ms Shreerupa Sengupta, Mr. Gunajit Kalita, Ms Deepika Wadhwa, Mr Jaggannath Mallick, Mr Pilu Chandra Das, Mr Subhojit Bhattacharjya, and Mr Parth Goyal. In the course of last seven years so, from 2014 to 2021, support for research in the India KLEMS project has been provided by Ms. Sanghita Mondal, Mr Vinay Sharma, Mr. Maajid Mehaboob Chakkarathodi, Mr. Anuj Goyal, Ms. Mehak Gupta, Ms. Prachi Madan, Mr Sk Md Azharuddin, Ms. Suchetna Pahwa and Mr. Samiran Dutta. The research team members do not words enough to thank these persons for the role they have played through their hard work and dedication for the successful completion of the India KLEMS research project. We wish to place on record our great appreciation of the review of the Report done by Prof. Hak K. Pyo, Professor Emeritus, Faculty of Economics, Seoul National University, Prof. H. Chun and Dr. K.H. Rhee, members of the Korea KLEMS team, and Prof. Minh Khuong Vu of Lee Kuan Yew School of Public Policy, National University of Singapore. We have immensely benefited from their comments and suggestions. A presentation on the Report was made at a Webinar organized by the RBI in July 2022. Valuable comments and suggestion were received from the RBI officers who were discussants at the Webinar. Detailed, excellent comments were received subsequently from the National Accounts Analysis Division of the Department of Economic and Policy Research, RBI. We express our gratitude to the RBI officers for the comments and suggestions that they have given which has helped us improve the Report. Finally, the research team wishes to place on record their appreciation of the work done by Ms Poonam Madan for copy editing the manuscript prepared by members of the research team. K.L. Krishna

Bishwanath Goldar

Suresh Chand Aggarwal

Abdul Azeez Erumban, and

Pilu Chandra Das

Chapter 1: Introduction to India KLEMS Approach 1.1 Introduction Economic growth and productivity at the global and country level is of major interest to researchers and policymakers, even more during global shocks and slowdowns, where the focus of economic policy becomes to rejuvenate “growth.” This gives productivity a prime place in academic research directed at understanding why some countries are able to do much better than other similarly placed countries in terms of the rate of economic growth and raising the standards of living. Going from the general to the specific, for India, a major emerging economy, productivity is the key force or driving engine for rapidly fostering the development and growth process.1 India has substantial economic potentials thanks to its enormous human and natural resources. Yet, the country is unable to lift in a short period the living standards of her vast population to sufficiently high levels owing to constraints of various kinds. A swift, substantial augmentation of productivity would enable India’s goods and services production units to penetrate in a much bigger way into the global export markets. Productivity improvements will help the country get better integrated into the global value chains and fend off the strong competition from imports that tends to displace domestic producers. It is also important for making small and medium firms more competitive, especially in the manufacturing sector, and for enhancing value addition in various economic activities securing higher profits, which would encourage further investments and higher remuneration for the worker. All of these will help make the size of the economy increasingly bigger and the Indian people progressively more prosperous. An understanding of India’s achievements regarding productivity advances, how productivity advances have contributed to economic growth, and the forces underlying the trends in productivity is obviously important both from an academic and policy point of view. While productivity can be measured using multiple approaches (Box 1), the discussion here is focused on introducing the KLEMS-based approach to productivity measurement in the Indian economy. The KLEMS approach takes into account the roles played by capital, labour, energy, materials and services as inputs in output growth. The evolution of the India KLEMS research effort is aimed at building quality as well as detailed disaggregated data for analyzing growth and productivity at the industry level in the context of the World KLEMS initiative, which aims at construction of comparable datasets for cross-country as well as country-specific detailed productivity analysis. A review of global literature on productivity research throws up some very significant studies indicating the importance of analysing the contribution of productivity to economic growth. Indeed, the research focussed on productivity as a source of growth makes an important contribution to the literature on economic growth. Box 1: Different Measures of Productivity | Productivity measures are useful in assessing a country’s economic performance. Productivity measures are categorised depending on whether they assess this performance using partial or all factors of production. A Partial Productivity measure relates output to a single input, such as labour, capital or energy. Of these, labour productivity, defined as the ratio of output to number of workers or number of hours worked is, the most commonly-used. With GDP (Gross Domestic Product) as the measure of output and number of workers as the measure of input, labour productivity is closely related to GDP per capita, which is a measure of the standard of living in a country. On the other hand, Total Factor productivity (or TFP) relates an index of output to a composite index of all inputs. In studies of medium-term or long-term economic growth, the usual focus is on TFP as the measure of productivity. TFP growth is often associated with innovation and technological progress, the long-run drivers of per capita income growth. Another distinction is between productivity measures based on value added (VA) or gross output (GO). Table 1.1 presents commonly-used productivity measures. Relevant productivity measures may be selected for different analytical purposes in assessing a country’s economic performance. | Table 1.1: Commonly-used productivity measures | | | Input Measures: K and L | K, L, E, M, and S | | Output Measure | Labour (L) | Capital (K) | K and L | K, L, E, M and S | | Gross Output (GO) | Labour Productivity Based on GO = GO/L | Capital Productivity Based on GO= GO/K | K-L TFP (MFP) based on GO | KLEMS TFP GO | | Value Added (VA) | VA/L | VA/K | K-L TFP based on VA | _ | | | Partial (Single) Factor productivity measures | Total or multi-factor productivity (TFP/ MFP) | Note: MFP denotes multi-factor productivity

Source: Adapted from Schreyer (2001) | | This report, titled India Productivity Report (IPR) provides the detailed analysis required to understand India’s performance since the 1980s, both at the economy-wide and disaggregated industry levels. The report is based on the India KLEMS database, version 2019, which includes important inputs as variables, such as capital (K), labour (L), energy (E) material (M) and services (S), at the industry level to construct estimates of labour and total factor productivity (TFP) across a set of 27 industries from seven broad sectors (Annexure 1A mentions the full list) using the growth accounting technique for productivity measurement and analysis (Box 2 outlines some measurement issues). This report devotes separate chapters to various aspects of the analysis undertaken, covering themes that have remained in focus and new themes added over the years, since the India KLEMS productivity study was launched in 2009. The report covers the analytical framework and detailed methodology as well as substantive empirical results for 27 industries, broad sectors and the overall economy. Alternative measures of output, including gross value of output and gross value added have been distinguished in the presentation of the results. The data sources and construction of variables are discussed in detail in the next chapter (Major point given in Annexure 1B). The period of study is from is from 1980-81(written alternatively as 1980) to 2017-18 (written as 2017) and includes periods of high growth (2003-07) as well as global slowdown (2008-17)2. Box 2: Evolving treatment of productivity in the global context | The OECD Productivity Manual 2001 provides a comprehensive treatment of various issues in productivity measurement at the aggregate and industry levels. Schreyer (2001) is a concise guide to the somewhat voluminous OECD Manual. Murray (2016) reviews the strengths and weaknesses of partial and total factor productivity measures from theoretical and methodological perspectives. Jorgenson (2018) reviews recent advances in the measurement of production/productivity and welfare within the National Accounts in SNA 2008.

Considerable progress has been made in addressing the limitations of GDP and the National Accounts. Chapters 19 and 20 in SNA 2008 resolved long-standing issues in the measurement of capital and labour inputs and made it possible to incorporate capital and labour services and productivity growth into National Accounts. Jorgenson highlights the fact that this resulted in a sharp reversal in the relative importance of the main sources of economic growth--productivity growth and accumulation of primary factors of production from the celebrated works of Solow (1957) and Kuznets (1971) using capital stock and hours worked.

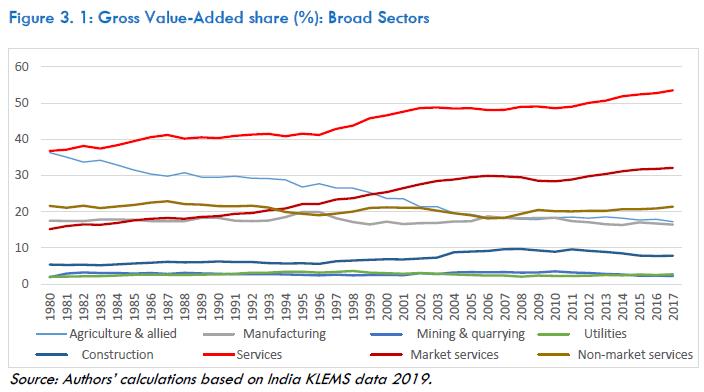

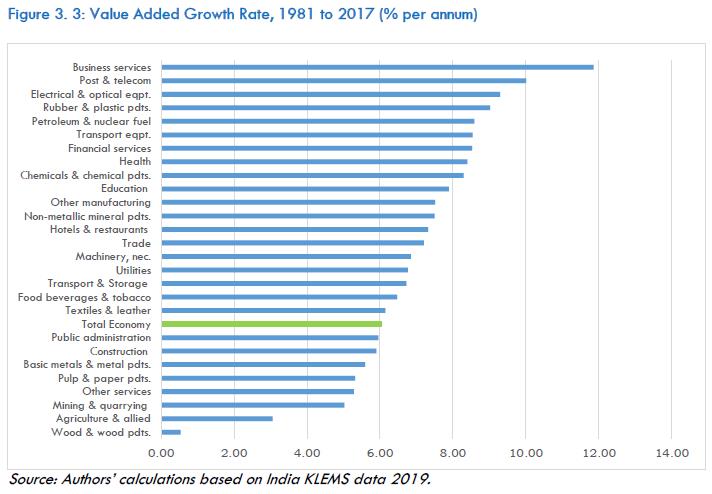

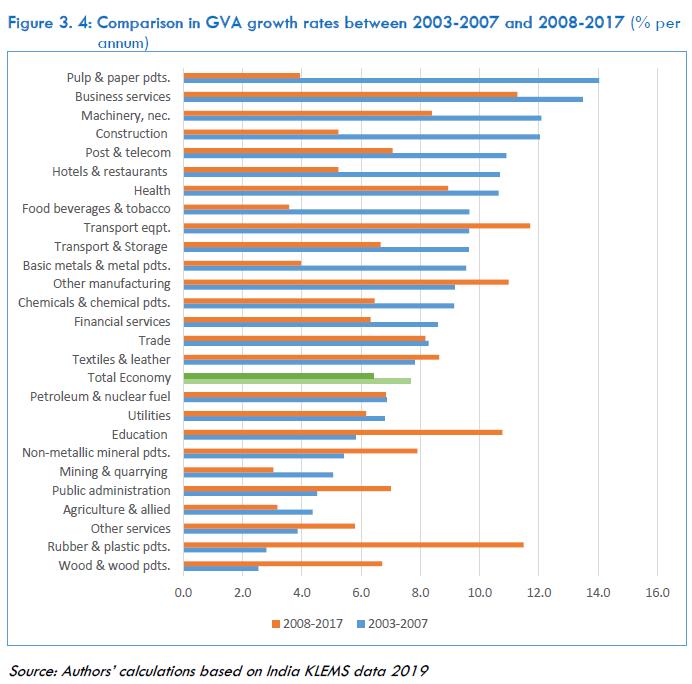

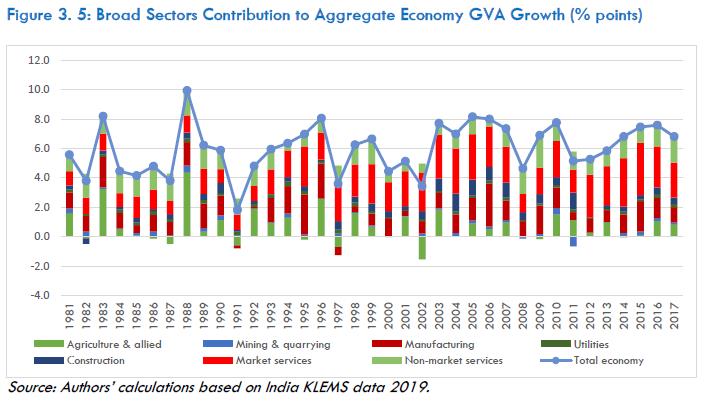

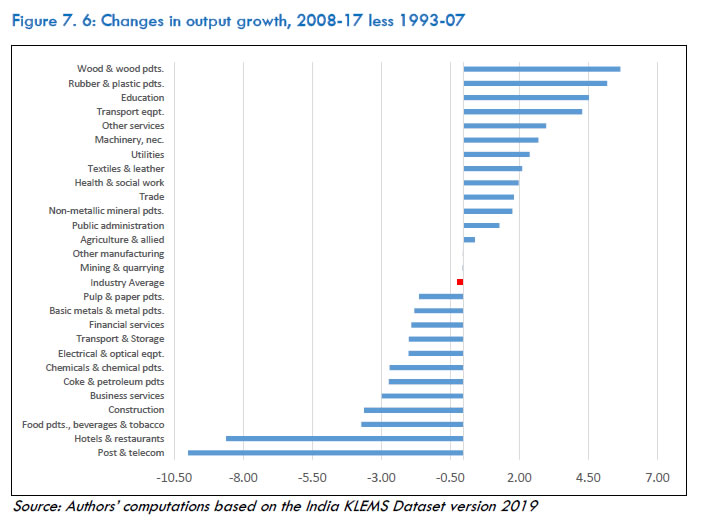

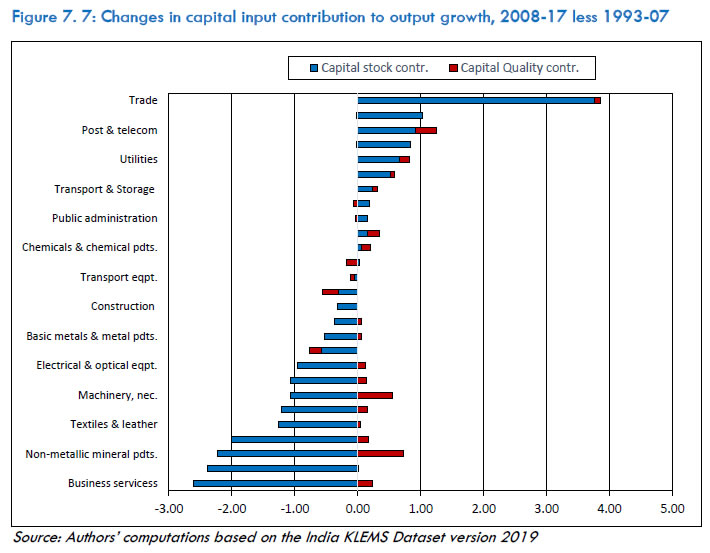

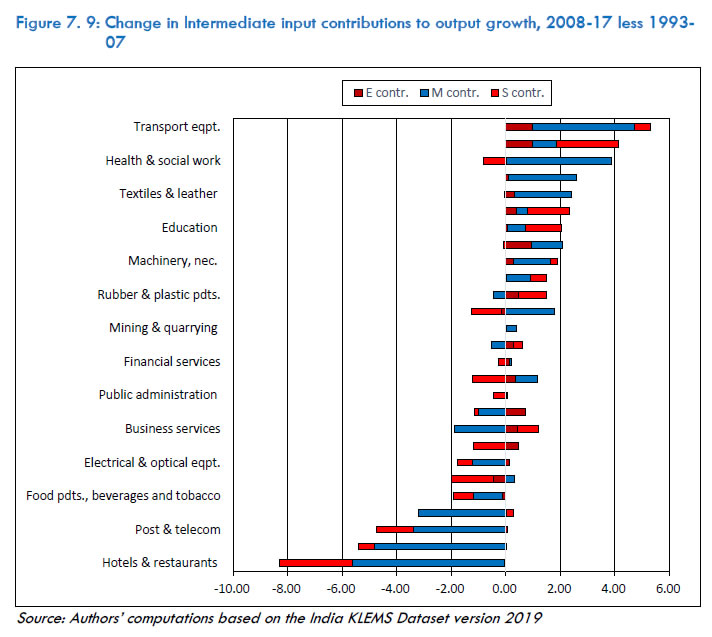

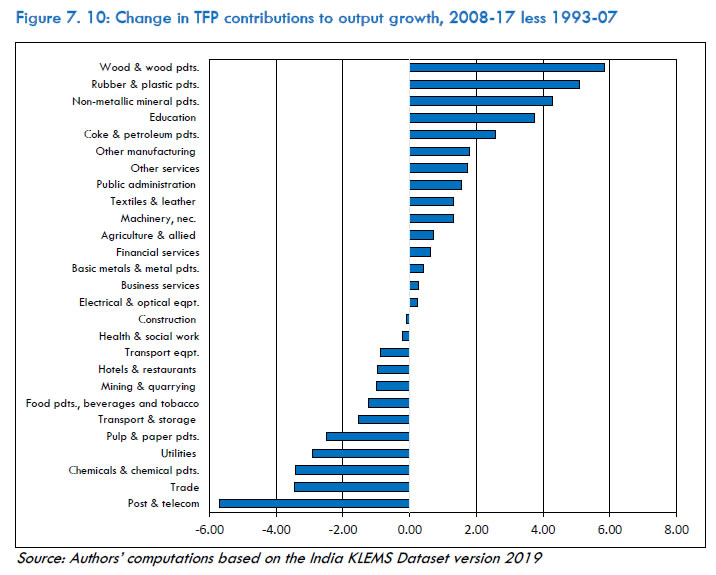

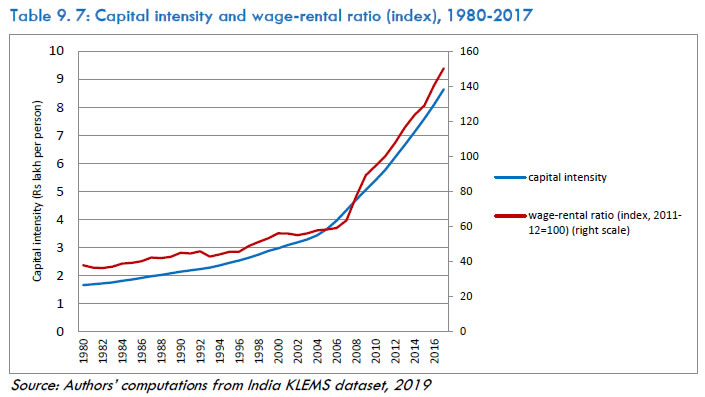

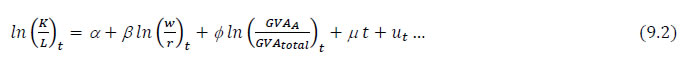

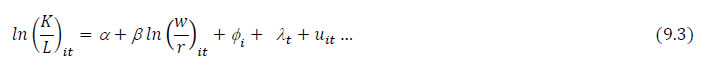

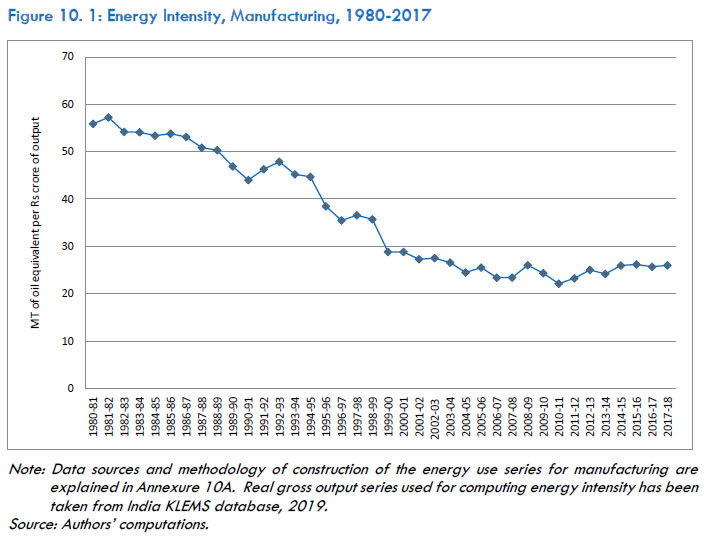

The OECD developed economy wide and industry level standards for productivity and capital measurement. These have been implemented for more than 40 countries through the World KLEMS Initiative and incorporated into the official National Accounts for 13 countries (Jorgenson 2018). The National Accounts for 199 countries have been linked through the World Bank’s ICP (Internationals Comparison Program) in 2011, which required aggregate PPPs for all countries to be constructed from relative prices for different commodity groups and linked to prices for the United States in dollars.